OLE Maintenance of UK Depots

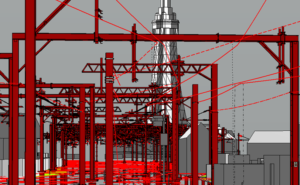

OLE Depot Maintenance.

ESL are contracted to maintain a number of rail depots across the UK. As part of this we undertake a programme of low-level and high-level inspections on a rolling programme. For a low-level inspection our engineers undertake inspections from the track and identify any potential non-compliances within the system as well as carrying out height and stagger surveys using laser gauges. High-level inspections involve a close-up survey of the equipment and are conducted by an OLE

Maintenance Engineer using a Mobile Elevated Working Platform. This includes checking the geometry and condition of the conductors and support and registration equipment; confirming electrical and mechanical clearances and torque settings; and making minor adjustments to the system where necessary.

Following each inspection a detailed report is produced based on an analysis of the system against design information. Any non-compliances are identified and a prioritised schedule of any recommended rectification works produced. Remedial or rectification works are then agreed and undertaken.

ESL have carried out surveys for various clients at the following depots:

1st-In-Rail

Hitachi – Newton Aycliffe

Hitachi – Ashford

Siemens – Three Bridges

Siemens – Ardwick

Norther Trains (NTL)

NTL – Manchester International Depot

Lowery

Southeastern – Ashford

Eurostar – Temple Mills

Project Description

ESL are contracted to maintain a number of rail depots across the UK. As part of this we undertake a programme of low-level and high-level inspections on a rolling programme.

Project Details

- Client: 1st in Rail

- Location: Nationwide

- Category: Overhead Line Electrification